By Lindsey Doermann | Originally published on the UW Chemical Engineering website

Advances in synthetic biology and biomaterials open up exciting prospects for distributed manufacturing of drugs, food products, and other commodities

During the world wars, American factories that ordinarily made cars and appliances changed up their production lines to manufacture guns, tanks, and aircraft in support of the war effort.

Fast forward to today when we’re facing a different fight, the adversary being a novel virus. When a disease spreads, certain drugs and their precursors can suddenly become as valuable as tanks and body armor. Is there a way re-tool pharmaceutical manufacturing, as industries did during the war, to help meet demand for valuable molecules?

An interdisciplinary research team that includes UW engineers thinks so — by employing a synthetic-biology take on wartime manufacturing. Their goal is to design flexible, plug-and-play modules that produce valuable products within existing fermentation equipment. Put another way, breweries, distilleries, and other fermentation facilities could adapt their “peacetime” operations to start churning out pharmaceuticals in response to public health emergencies.

The group is led by soft-materials specialists Lilo Pozzo of ChemE and Alshakim Nelson of Chemistry; synthetic-biology experts James Carothers of ChemE and Hal Alper of University of Texas, and small-scale automation expert Nadya Peek of HCDE. The team recently received NSF funding to develop the technology and prototype modules for distributed chemical manufacturing. Here’s how it would work.

Many of our drugs or drug precursors derive from plants. Aspirin originally came from tree bark, opiates have been farmed from poppy flowers, and the anti-cancer agent Taxol was derived from the bark of the Pacific Yew tree. The anti-malarial artemisinin is still largely sourced from the leaves of sweet wormwood trees farmed in Asia and Africa.

But when it comes to pharmaceutical production, Pozzo points out, “plants are inefficient because the component you want to isolate may exist in very, very small quantities.” Thanks to synthetic biology (SynBio), researchers can hack this process by genetically modifying bacteria and yeast cells to overproduce desired chemicals. Think of it as a sophisticated form of brewing beer.

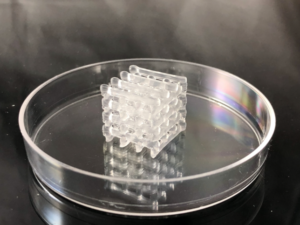

In a February Nature Communications paper, Nelson and Alper reported a major step toward making SynBio systems portable and adaptable. They discovered how to embed genetically-modified microbial “factories” within a 3D printed hydrogel. In this configuration, they can constrain chemical production to within the gel (as opposed to dispersed in a large fermenter), run reactions continuously, and even grow more than one microbe within a bioreactor.

Now, chemical engineers can help move the ball further. In the new project, the ChemE’s will focus on developing new materials that optimize the transport of both the nutrients into the system and the chemical product out. Extracting the end product efficiently has long plagued this technology. But now, with the hydrogel framework and chemical engineers at the ready to solve some transport problems, it has new potential.

In parallel with the ChemE work, HCDE’s Nadya Peek will take the lead on designing the human-centered automation workflows for the modules. “You have to think about the human aspect of this,” says Pozzo. “Users may not have the same levels of expertise.” To be successful, the team needs to create a system that’s plug-and-play, works within existing infrastructure, and doesn’t require PhD-level training to operate.

The multifaceted project offers exciting opportunities for students, as well. Pozzo is developing design projects for ChemE undergraduates that look at the economics of different products that could be made by the SynBio systems. Students could consider not only chemical production aspects — e.g. how hard is it to make a given molecule? what are the yields using current methods? — but also the demand and market forces. The researchers view the modules as a flexible platform, and Pozzo thinks the students can help reveal just how flexible it can be.

In fact, she thinks the pharmaceutical materials are only the beginning. If you can make plant-derived drugs this way, why not other plant or even animal-based products? In the burgeoning field of cellular agriculture, microbial “factories” can replace some traditional farming operations to produce our food. In farming, animals serve as rather inefficient bioreactors to produce meat, milk, and eggs. But cells in SynBio systems are capable of producing the same things in a climate-friendlier manner, bypassing animals altogether.

Factories are traditionally designed to make one product. Reconfiguring an auto plant to produce ventilators, however critical, is a big undertaking. But think: if your factory is a cell, then reconfigurations occur on the micro scale. “You wouldn’t need to have large-scale manufacturing if you could design a cartridge, for example, that you could plug into existing fermentation equipment,” says Pozzo.

Breweries, distilleries, and commodity chemical producers exist all over the country. What if they became a network of “farms” for food or pharmaceutical products that can adapt to emergency shortages? What if microbial factories could supply some of the food we eat every day? It turns out that a big idea for a new way of manufacturing may actually be microscopic.

This work is funded through the National Science Foundation’s Emerging Frontiers in Research and Innovation (EFRI) program, which invests in high-risk, high-reward multidisciplinary research.